Sweet dreams are made of this

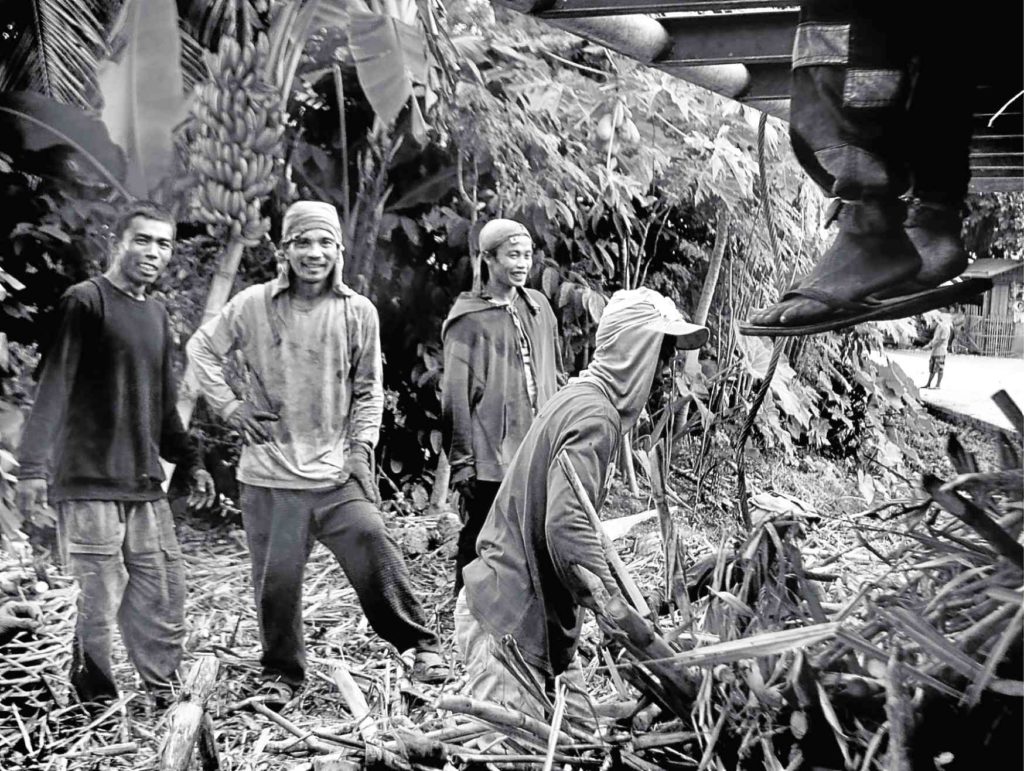

Clutching a sickle, farmer John Godinez dons a battered orange helmet and enters a field of razor-sharp grass six feet high.

In the endless sprawl of sugarcane blanketing Negros Occidental, 300,000 farmers like him till the land for the sweetest crop of them all.

“I’ll get about P500 for weeding a hectare of land,” he says. “Life is tough. I’ve been doing this for 20 years and I still can’t afford to raise a family.”

Once dominated by elite landlords called hacienderos and held back by the difficulty of securing farm loans, sugarcane farmers haven’t had a sweet deal—but a new system might just change the way sugarcane is farmed.

Agricultural sustainability

Known by many Filipinos as tubo, sugarcane (Saccharum officinarum) isn’t far different from the wild talahib (Saccharum spontaneum) lining many fields. It’s just grass—but it changed the world. About 30 Philippine mills convert canes into raw sugar, while 12 refineries process raw sugar into the refined sugar we’re familiar with. In 2012, the country produced 2.5 million metric tons of sugar, valued at P70 billion. Negros Occidental alone supplies half of this, but many of its workers don’t earn too decently.

But there’s good news for sugarcane farmers.

Doubling output

To drive up productivity and sustainability, partners are coming together in Negros. “Our goal is to produce more sugar using less resources,” says Federation of Multi-Sectoral Alliance for Development executive director Reynic Alo. “Whereas a typical sugarcane plot produces from 50 to 70 metric tons per hectare, new practices can double output. As opposed to the usual planting of sugarcane in ordered rows, we pilot-tested a new method called CluMP, short for ‘Clustering Method of Production’. It uses evenly-spaced, 40-centimeter deep holes planted with four sugarcane tops. Through proper upkeep and plant nutrition, our new system just generated 105 tons per hectare—over twice traditional yields.”

The CluMP method also encourages crop diversification by having farmers plant cash crops like corn and legumes between sugarcane clumps and on hills. This provides short-term income and is a climate-smart approach to agriculture.

These canes weigh over a kilogram each and are ready to be processed. They can be chewed raw as tubo when stripped of their tough bark or milled into molasses and sugar crystals. A hundred tons of raw cane can be pressed and processed into around 12 tons of sugar and four tons of molasses.

CluMP might just be the magic bullet the country needs to compete with sugar giants like Brazil and Thailand.

Roxas Holdings Incorporated (RHI) has provided technical farm assistance to enlisted farm cooperatives, while pushing for sustainable farming practices. The company is also helping identify alternative crops and livestock to tide farmers through the dreaded “tiempo muerto” the low-season from April to August, when farmers must patiently wait for the sugarcane to grow to harvestable sizes.

“Despite the country’s ever-growing demand for food, most of our farmers remain poor. We’re working with many allies in both Negros Occidental and Batangas to gather and share best practices for growing and processing low-impact but high-yield sugarcane. We’re transforming lives through better farming solutions,” explains WWF-Philippines project manager Moncini Hinay, who formerly led a nationwide study on climate change resilience.

The Philippine agriculture sector accounts for 40 percent of the economy but emits 30 percent of the country’s greenhouse gases, fueling dangerous climate change. Floods, droughts, diseases and other climate change effects can cripple farmland.

“Water use, soil erosion, land conversion, pesticides and pollution must all be addressed to ensure agricultural sustainability. How can we feed ourselves if our natural systems can no longer support crops? Mainstreaming climate-smart agriculture is essential in strengthening the resiliency of our agriculture sector,” concludes Hinay.

There are many challenges facing the country’s sugar industry, which has been on the decline since the 1970s and is now threatened by an avalanche of cheap imported sugar, plus sugar alternatives like high-fructose corn syrup.

With better financing, education and innovation, the Philippine sugar industry can again rise and offer better tidings to its farmers.

Back in the blistering sugarcane field, John’s work is done. He seeks shade and breaks bread under a clump of swaying bamboo. Negros Occidental’s sugarcane farmers still stand tall and tough—just like the canes they harvest. Yes, the sugarcane industry has for 300 years been a bittersweet symphony. But with new ways of farming and financing, its people might finally get the sweet deal they deserve. —CONTRIBUTED