‘Hablon’: From place mats to wedding gowns

ARGAO, CEBU—Maribel Salandron had thought that the “hablon” she wove by hand would only be material for place mats and coasters. She could not believe that the fabric had been sewn into an elegant bridal gown.

“It is an overwhelming feeling to see our work receiving this much attention. My ancestors would never believe this,” said Salandron, 37.

The transformation was made possible by Cebuano fashion designer Dexter Alazas, who fell in love with the hablon in 2007 while looking for a unique fabric that would represent Cebu province.

Alazas elicited the support of the Department of Trade and Industry (DTI) to revive the hablon community in Argao by using the handwoven material in the gowns and resort wear for a local pageant, Dalagang Argaoanon.

Teaching weaving

In March last year, the DTI installed 20 handloom weaving machines worth P825,000 at Cebu Technological University (CTU) in Argao through the agency’s shared service facility program. CTU had then started to implement its Hablon Extension Program to teach hablon weaving to its first batch of 20 students and 20 residents.

What was dubbed as a sunset industry in the southern Cebu town received another lease on life as government agencies, business organizations and the academe worked together to revive the native art of weaving. The partnership was bolstered by Alazas’ vision to push for a unique Cebuano fabric that could join the ranks of world-class, Philippine-woven fabrics such as the Ifugao tapis and the T’boli t’nalak.

“If I just use fabrics imported from other countries, I feel that it’s not original, it’s not innovative. I want to create a brand that elevates Cebu fabrics because I represent Cebu,” said Alazas, who owns Alazas Atelier.

Hablon comes from the Cebuano word “habol,” which means to cover with a cloth. The weaving process is called hablon while the woven product is called hinablon. But for brevity, the term hablon has been used to refer to this handwoven fabric or textile.

Different fibers

Different types of fibers are used in making hablon. These include polyester, abaca, rotex and tingkal (cotton strands).

In the past, abaca fiber was used to create hablon and the households of Argao were known weavers.

Weaving is often done in the homes, with the skill passed on from one generation to the next.

Salandron learned to weave when she was 14 by observing her grandmother, mother and older sister. The family was living in Barangay Tayag, a mountain village located 18 kilometers from the town center.

A fourth-generation hablonera, Salandron remembered assisting the older women in weaving. They would usually produce 120 meters of fabric in a week, she said.

A meter is sold at P2.50. It was a feast in their home when they earned between P300 and P500 a week.

Today, she can produce four to five meters a day at the CTU Argao work station. Each meter sells for P80.

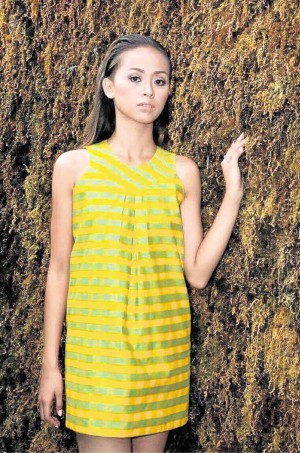

Alazas recently expanded his handwoven line under the name Linya Sugbuana, bringing a wealth of opportunities to Salandron and her fellow habloneras.

“This is an entire lifestylee line that will showcase the best of Cebu. This is my way of supporting our local creations and making them part of mainstream fashion,” he said.