SHAPII makeover: From traditional to trendy

SALAY, Misamis Oriental–“We have grown. We are no longer the same company,” Loreta Rafisura, president of Salay Handmade Paper Products, Inc. (SHAPII), declares.

She says this with a half-happy, half-wistful look.

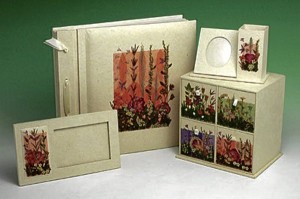

In the “good old days,” SHAPII was known for handmade paper products with intricate flower designs. Greeting cards, desk and stationery sets, boxes, calendars, picture frames, photo albums, lampshades– all embellished with tiny pressed flowers. “Pressed flowers on handmade paper was SHAPII’s trademark for many years,” Loreta recalls.

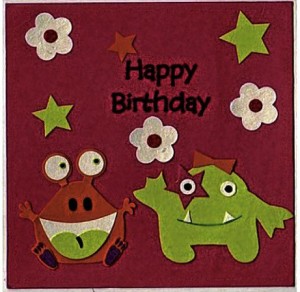

Her son Neil Francis, SHAPII General Manager, describes the recent changes: “Today, we use patches, sequins, glitters, threads, and cut-outs from different materials. The flowers are still there, but no longer so ubiquitous — and the presentation has become young, colorful, trendy.”

“To me, it feels to me like it is no longer us,” Loreta interjects. “Even the handmade paper we now produce has become so fine it has lost the quaint quality I love.”

Neil confirms this. What used to be coarse, off-white, gross-grained sheets have been refined. They are now thinner, whiter, more exquisite. The company has begun using new materials. ”

Capiz shell, for example, is powdered, then sprayed with water and mixed with the slurry so that it becomes part of the paper, giving the sheets a silvery finish.”

Royalty

Time was when SHAPII workers were encouraged to create their own designs based on an approval system of which Loreta was the judge. “We sent the prototypes to our clients. If they liked it and ordered, the worker who originated the design got a royalty from the sales, at 15 centavos per greeting card.”

When the designing process was professionalized, the royalty scheme was dropped. “Something got lost in the process,” Loreta rues. “We are tied up to new rules. But we became more customer-led and got more orders.”

It was Neil’s tour of Europe in 1997 that triggered major changes in product design.

Under a DOST Global Technology Search (GTS) grant, Neil observed product and marketing trends in England, Holland, and other countries in Europe. There, he met with paper design consultants.

Shown the SHAPII products Neil brought with him, the European consultants found the designs too conservative and traditional and predicted they would not sell there.

With training from Clara Gonzales, formerly a DCCP designer, SHAPII put up a product development team of 12 people selected from among the work crew for their artistry, discipline, values, and ability to cooperate.

New team

The team now creates new designs which are sent to buyers. If buyers like them, they ask for a sample, usually with their own revisions. The team then picks it up again. “The work may sound simple.” Neil says. “But it is madugo (tedious) to comply with the revisions. Color dimensions are especially tricky.”

They look for solutions, in terms of mechanization and technology, for example.

Solutions are not hard to find if you know where to get help, Loreta offers.

In 2004, SHAPII stepped up its mechanization program for the paper-making department through a loan from Shared Interest, a UK financial Fair Trade facility.

In 2006, it put up an environmental management system, including a waste treatment facility, with the help of a grant from Ten Thousand Villages, Canada.

In the past, SHAPII was, in Loreta’s words, a DTI baby, then a DOST baby.

DTI and DOST are the Department of Trade and Industry and Department of Science and Technology, respectively.

SHAPII began in 1987 as a project of the DTI’s People’s Economic Council (PEC). As such, they received support from the agency in capacity-building, paper-making training and marketing. “DTI introduced us to buyers from Penny’s of the US. I think they fell in love with me, my candor and sincerity. That led us to export,” Loreta recalls.

DOST supported their early product development, production improvement, and technology acquisition efforts, after SHAPII left the PEC and incorporated in 1990. Their first set of modern equipment was obtained with easy loans from DOST, which also sent experts to improve factory layout and workflow.

From this experience in growing SHAPII, Loreta urges new businesses to pro-actively seek assistance from government and other support agencies. Networking is the key, she asserts.

Loreta also wants to spread around the Fair Trade philosophy, still little known in the country. She tells other businesses that when foreign buyers come, they look for Fair Trade products.

The international Fair Trade Movement aims to help producers of handicrafts and agricultural produce in developing countries get better trading conditions and achieve sustainability. It advocates the payment of a higher price – known as social premium—to exporters from these countries and promotes social and environmental standards.

Fair Trade came to SHAPII in the early 2000s with the visit of a Traidcraft UK Staff, accompanied by then Advocate of Fair Trade Manila Executive Secretary Nette Ocampo. “They found out that essentially, instinctively, we were already practicing Fair Trade principles,” Loreta recalls. They were then invited to join the global World Fair Trade Organization.

Growth

SHAPII has grown phenomenally from the time it was a PEC project. From P6,000 starting capital, it is now worth P20 million. From 10 Salayanos who completed paper-making training in 1987, the company now has 250 workers, 14 of whom are now stockholders through a salary-deduction scheme. From store-to-store selling in Cagayan de Oro which saw Loreta “practically begging for orders,” the company has entered international markets in the US, Japan, and Europe.

There were trade-offs. As Loreta says, some things got lost in the concession to growth. But then, in the cycle of things, the old must give way to the new, just like Loreta lets go more and more of the management ropes to son Neil.

Other passions

The better for Loreta to indulge in her other passion, the SHAPII Foundation, which carries out the social outreach goals of the company. The Foundation has a roster of 45 scholars, a vermiculture project, a community reading center, and a computer facility room.

SHAPII is one of the enterprises to be featured in an upcoming book by the Small Enterprises Research and Development Foundation (Serdef) on “Product Strategies of Small Business.” For more articles on how to start and improve a business, visit the Serdef website at www.serdef.org.