New advances in construction technology

New technologies are enabling the development of innovative, environment-friendly building materials.

In this column, we have mainly concentrated on how new web3.0 technology is poised to radically change the property industry over the next decade.

We’ve talked about smart contracts, virtual tours, and blockchain decentralized financing. However, one area we should probably touch on is how the actual construction process is going to change forever.

Sustainable building materials

Thankfully, there is a rising emphasis on sustainability in the construction industry. New technologies are enabling the development of innovative, environment-friendly building materials such as self-healing concrete, recycled building materials, and even 3D-printed materials made from recycled plastics. These materials have a great potential to make high-rise condominiums and office buildings more energy-efficient and environmentally benign.

Modular construction and prefabrication

Modular construction is not a new concept. The practice of prefabricating “modules”—which are built off-site and then assembled on-site—has had bursts of popularity over the years, especially in post-war America when there was a need for fast construction amid manpower shortages. However, it was often seen as cheap and somewhat tacky.

The rise of 3D printing, automation robots and digital modelling is now changing the perception of modular construction, and has resulted in a resurgence of this practice, particularly in Japan and Scandinavia. It cuts down on construction time, waste, and overrun costs.

For example, 93 percent of the 30-story Tower Hotel in Yueyang, Hunan province was assembled off-site by 900 workers. The actual construction of the building only took 15 days, with only 10 percent of the usual concrete usage, and less than 1 percent of the usual waste.

3D printing

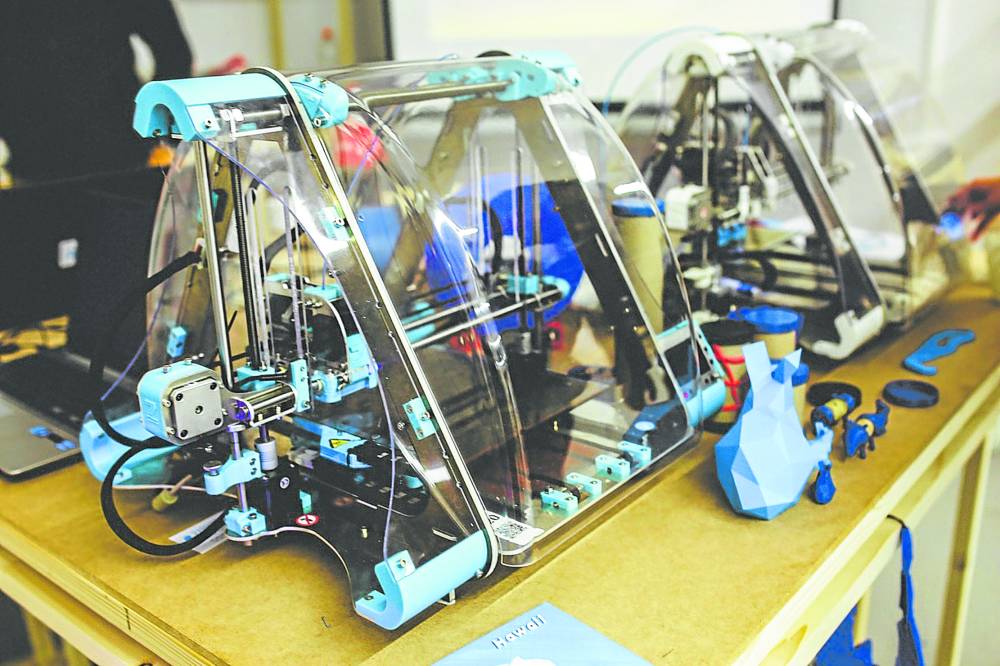

3D printing will become increasingly prevalent as prefabrication becomes more integral to the industry

While still a niche area in property construction (and mainly used for residential homes, not high rises), 3D printing will become increasingly prevalent as prefabrication becomes more integral to the industry.

A 3D printer receives instructions on what to produce, and machines begin to overlay material layers according to the instructions. This can be accomplished using a variety of materials, the most typical of which being a mixture of concrete, geopolymers, fiber, sand, and even rice waste.

While 3D printing has huge benefits for the industry, a couple of elements are halting its growth. The printers themselves are expensive, and there is still a shortage of trained professionals to manipulate them. However, over time the costs are expected to shrink with economies of scale, and more trained technicians will gravitate to this exciting new industry.

Renewable Energy

New technologies are making it easier to include renewable energy sources into high-rise condo designs, such as solar panels and wind turbines. HVAC systems, lighting, and insulation materials are also becoming more advanced in terms of energy efficiency.

With energy costs rising worldwide, and an emphasis by most governments on climate change and renewable energy, projects that have a focus on renewable energy sources will certainly stand out in the market.

All of these elements are being utilized to a certain extent right now, but are still a fair way from being adopted as standard industry practice. Over the next five to 10 years, we will see more construction companies invest in prefabrication factories and off-site processing, while keeping a closer eye on efficiency and renewable energy.

The author is the COO and digital co-founder of PropertyAccess