Longevity and beauty in Yakisugi

On a recent trip to Kyoto, I was marveling at the timber work, checking my phone’s weather app every day, trying to figure out the humidity levels as I’d always wondered how the Japanese managed the use of wood in their beautiful traditional and modern constructions when their weather is just about as rainy and wet as ours.

Well, another app confirmed that we have more rainfall than Japan, but we enjoy more sunny days. And yes indeed, they have lower levels of humidity but not in the category of dry air. In different parts of their country, wooden structures are designed differently, and age differently too, depending on the local microclimate and the construction methods that evolved over time.

Elevated structures

Considering this aspect of their weather, one of the ways the Japanese traditionally kept their wooden structures from deteriorating was to elevate them from the ground.

An entryway made dramatic with the natural timber finishes enhanced by its contrast to the charred wood (NAKAMOTO FOR- ESTRY)

Quite like our “bahay kubo”, elevated structures work with the principles of tropical design and promote the free flow of air, pushing out humid air and replacing this with dry and clean air, thus hampering the growth of molds and fungus. They also have expansive doors and window openings which allowed for the exchange of a larger volume of air.

‘Charred wood’

Another way they preserved timber was through the Japanese process of using charred wood for the exteriors of their structures.

Popularly known in the west as “shou sugi ban” but more appropriately termed as “yakisugi”, this process involves charring the exposed surfaces of wood, then brushing off the charred layer while allowing a layer of carbon to remain, revealing the beautiful natural texture of the wood grain underneath.

Different levels of charring and sanding result in different aesthetics for yakisugi. (NAKAMOTO FORESTRY)

This process improves the durability and resistance of the wood not only to humidity and weather, but to fire and the intrusion of insects as well. Japan has a forest cover of some 66 percent, and is dense with “sugi” or cypress, also known as “Japanese cedar” which is the ideal wood for yakisugi.

The yakisugi method is applied to planks that will be utilized for exterior cladding and other exposed surfaces prone to weathering. It is also much appreciated globally for its aesthetics and its eco-friendly properties, being treated naturally, and its qualities from raw to finished, magically transformed by fire.

Traditional method

So what are the steps in the yakisugi process of charring wood? Let’s go through the traditional method.

The first step is the selection of the timber planks, the most suitable species being cedar or Japanese cypress. Next, the surface is prepared by cleaning away dirt, debris, and any loose bark. It is then sanded and smoothened before the actual charring process to ensure that the surface is smooth, flat, and even. Then, the surface of the wood is charred by exposure to fire.

Traditionally, cedar planks are bound and tied into a hollow triangular configuration—think Toblerone—and are positioned vertically, after which a fire is lit at the bottom using mainly newspaper, and the flames are allowed to run upward, burning the length of the plank. The heat must reach between 250 and 400 degrees, and after five minutes of burning, the planks are unbound, opened, and the fire is allowed to extinguish.

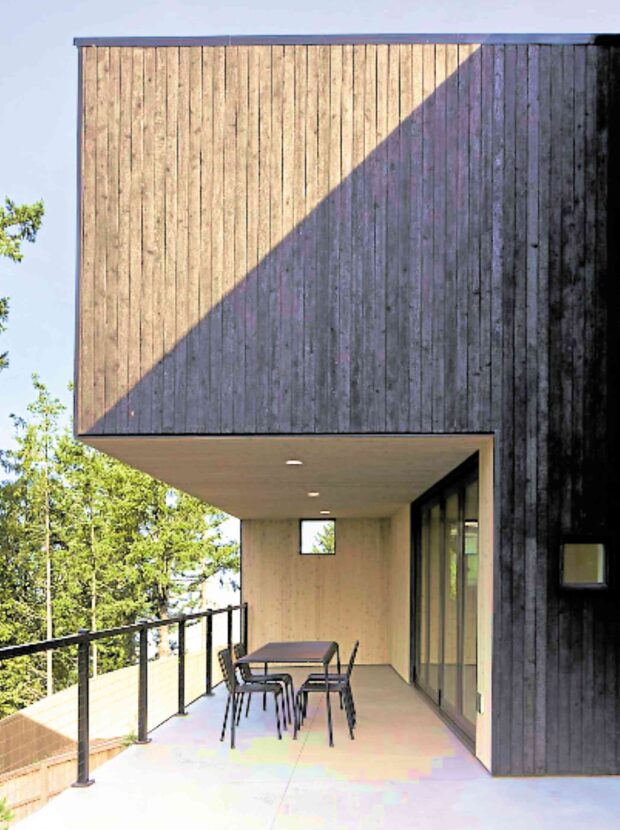

This three-level terraced residence employs both charred and natural timber for a modern contrast of surfaces in its geome- try. (OPEN STUDIO COLLECTIVE VIA DEZEEN.COM)

The char should be uniform and cover the entire surface of the wood. The level of charring depends on the desired finish and the type of wood, with Japanese cedar being one of the best, due to its natural wood oils.

The wood is allowed to cool slowly for several hours allowing the charred layer to stabilize. The charred surface is then brushed with a stiff-bristled brush to remove most of the charred layer and allow the wood’s natural grain to show through.

This may vary depending on preference. Some sanding may also be done for a smoother finished texture. The surface is then wiped with a damp cloth to remove any residual soot. For the final finish, a protective coat may be applied. Oils may be wiped on with a cloth, or a wood seal can be brushed on to help protect the timber further although this is not the traditional way.

Modern variations

Keep in mind that shou sugi ban is a traditional Japanese technique, and there may be variations in the process depending on the region or the individual craftsman. Modern iterations, variations in wood species, sizes, and colors may affect the outcome of yakisugi.

In these modern times, yakisugi is done on a commercial scale with timber suppliers charring their wood in kilns. In smaller on-site applications in the west, charring is produced with a propane torch or a gas burner.

A home in Australia wrapped with timber treated in the tradi- tional yakisugi method of preserving wood (HABITUSLIVING.COM)

While the yakisugi method works well for Japanese cedar, it may not be as effective for other species of timber. Moreover, experimenting with this method in locations that are different from the Japanese climate may deliver different results, perhaps requiring more maintenance and replacement, or the timber may age differently.

Nonetheless, the beauty in applying yakisugi allows for some experimentation with results that may not align with tradition but may serendipitously allow us to discover new ways of preserving wood and applying aesthetics by way of fire.

The western world is indeed catching on to this method through its own beautiful iterations of yakisugi!