Are we ready for timber buildings?

Wood has been one of the most common construction building materials ever since the dawn of civilization. Throughout history, buildings have been made of wood. Japan and China, having a long tradition of timber construction, have enormous wood structures that continue to stand today. Scandinavia, a country with heavy forests, has had much experience with timber construction. There are also notable examples from France, Holland, Germany and Switzerland with varying architectural styles.

Wood, however, has several disadvantages such as water damage, fire, decay and termites. The early 20th century hence saw a shift towards bricks, concrete, and steel, which allowed architects to design new and innovative buildings.

So, why are some architects recommending a return to wood construction after a century of concrete and steel?

Concrete and steel are costly to produce, consume a lot of energy and are heavy to transport. Wood, however, can be grown sustainably and is lighter than concrete. As trees grow, they absorb carbon dioxide from the air, locking it into the timber. Regular timber cannot compete with the strength of concrete and steel and is not strong enough to build high-rise buildings, but engineers have found a solution. It is called cross laminated timber (CLT) or glue-laminated timber (glulam).

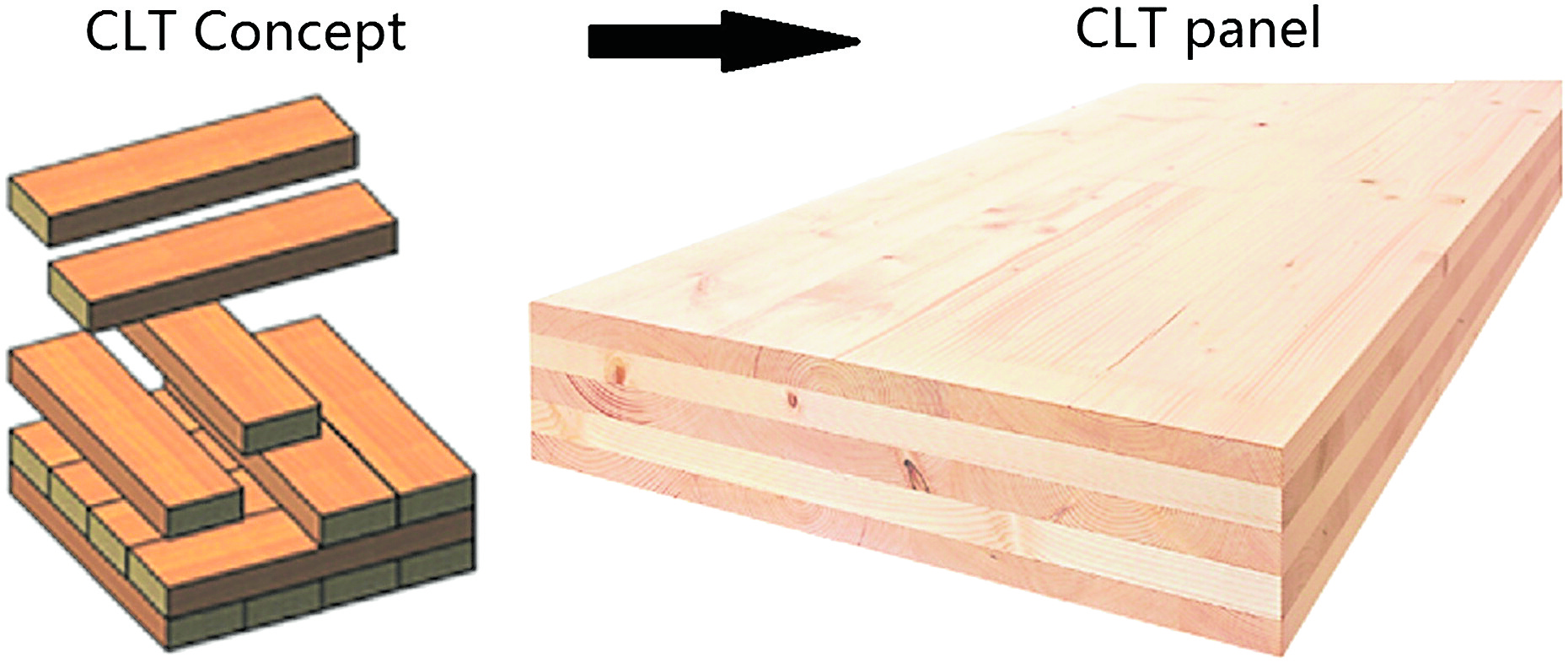

Cross laminated timber or glue laminated timber is made up of wooden planks that are sawn, glued, and layered.—ASCE LIBRARY

What is cross laminated timber?

CLT is made up of wooden planks that are sawn, glued and layered, wherein each layer is oriented perpendicular to the previous plank. By joining layers of wood at perpendicular angles, it gains structural strength for the panel. This results in an extraordinarily strong and stable material. CLT is a sustainable material because its basic material is wood, a renewable resource. It also does not require the burning of fossil fuels during its production. CLT is light and it is comparable in strength to concrete and steel.

What happens when CLT is burnt?

It loses some of its structural mass, but when you remove the heat source, it extinguishes itself. When steel is exposed to extreme heat or flames, it gets a bit softer. This is what happens when some steel roofs collapse in fires, whereas wooden roofs have not.

Uses of CLT

The panels can be used as floors, walls and ceilings with the dimensions following the requirements of the project. They can also be used for infrastructure and large construction sites, as forms for concreting bridges. Today, CLT components are being used even in skyscrapers.

There are several advantages in using CLT: shorter construction time, greater quality control and more efficient cleaning. It is exceptionally light particularly compared to concrete and steel, so it is possible to build taller buildings on the same sized foundations.

Mjøstårnet by Voll Arkitekter in Brumunddal, Norway is the world’s tallest timber building. —DEZEEN.COM

New generation of timber buildings

In Brumunddal, Norway, Mjostarnet by Voll Arkitekter is the tallest timber building in the world, according to the Council on Tall Buildings and Urban Habitat. Standing at 280 feet (18 stories), the new building is called “playscraper” in Norway. The builders used glulam and laminated timber beams, which are strong enough to replace carbon-intensive concrete and steel. To overcome strong external forces, large-scale columns and trusses were utilized. The building was tested for fire safety and was designed to withstand a complete burnout.

Oakwood Timber Tower in London is the city’s first timber skyscraper with conceptual plans for an 80-story, 300-meter-high wooden building integrated with another building. The project includes 1,000 new homes within the 93,000-sqm floor plan, integrated with mid-rise terraces.

Mactan Cebu International Airport has the first roof structure in Asia to be completely made from glue-laminated timber. —CAPA-CENTRE FOR AVIATION

Mactan Cebu International Airport (2018)

The second largest airport in the Philippines has the first roof structure in Asia to be completely made from 4,500 m3 of glue-laminated timber. It has a height of 15 meters and a span of 30 meters. The large arches are joined by thousands of smaller ribs to form a skeletal structure. The timber beams were prefabricated in Austria and assembled in Cebu in only three months.

For Clark International Airport, the wood used in the glulamtimber roof arches is made from white spruce imported from Austria sourced from sustainable commercial forests.—CLARK INTERNATIONAL AIRPORT

Clark International Airport New Terminal (2020)

The new, modern passenger terminal, located in a special economic zone, is expected to be the next premier gateway of Asia, connecting travelers throughout the region. The wood used in the glulam timber roof arches is made from white spruce imported from Austria sourced from sustainable commercial forests.

Future of CLT in PH

With the completion of the Mactan Cebu International Airport and the Clark International Airport, a new era in timber construction has just begun. The question is: will this be the start of the construction of timber buildings in the Philippines?

Before the technology can be adopted in the country, there are two issues that must be addressed. First is the issue of sustainable forests.

Sustainable forests refer to an effective and efficient management system to replace trees that are cut so that forests continue to exist. Without a sustainable forest management system, the idea of promoting timber construction would be disastrous as trees are depleted without replenishment to supply the new building technology.

The other issue is the embodied energy of materials. To reduce carbon emissions, it is preferred that locally sourced (or regionally sourced) materials are used rather than those from distant locations. Embodied energy refers to the energy consumed as a product goes through the process of mining and processing of natural resources to manufacturing, transport and product delivery.

The author is the principal architect of A.P de Jesus & Associates-Green Architecture and vice chairman of the Philippine Green Building Initiative. For comments or inquiries, email amadodejesus@gmail.com