Maximizing opportunities in supply chain management

Is your company customer-centric? Do you prioritize sustainability? Are you using intelligent technology? Are you data-driven?

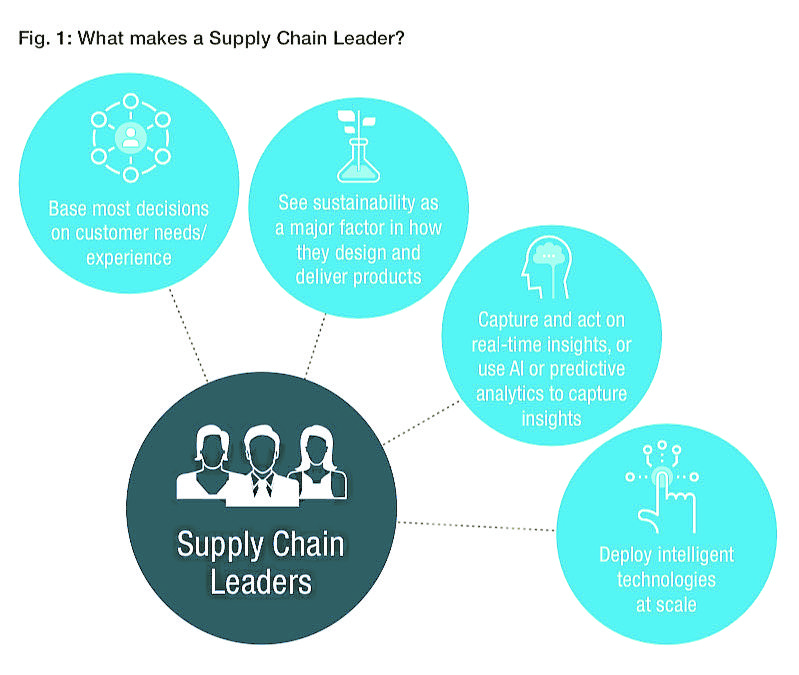

Strive to answer “yes” to all four questions so you can become a “supply chain leader,” especially amid this pandemic, says the report by enterprise application software provider SAP and Oxford Economics, “Surviving and Thriving: How Supply Chain Leaders Minimize Risk and Maximize Opportunities.”

The report details results of a global survey of 1,000 executives who are decision-makers, or at least influence decision-making, on their companies’ supply chains. Industries covered by the study are manufacturing (19 percent); consumer goods (17 percent); energy and natural resources (15 percent); telecommunications (10 percent); pharma/life sciences (10 percent); high tech (10 percent); construction (8 percent); travel and transportation (8 percent); and engineering (5 percent).

Core principles

While data was gathered early this year, before the widespread coronavirus outbreak, the report states that it still “sheds light on core principles of supply chain management that will help companies navigate the uncertainty ahead.”

Of all the respondents, 12 percent were tagged by SAP as Supply Chain Leaders, or those successfully managing their supply chains because of stronger strategies for customer-centricity, visibility, sustainability, and the application of intelligent tech.

Article continues after this advertisementSo what sets them apart?

According to the report, Supply Chain Leaders “may have a more nuanced view of what satisfies customers than other respondents.” Non-Leaders, when asked to choose which factors are most important in achieving customer satisfaction, picked the usual: product and service quality, price, and speed of purchasing experience. On the other hand, Leaders’ choices also included “support through product life cycle,” and “ethical product sourcing,” which, the report states, shows that these executives and their companies are ensuring that engagement with customers continue even after their product has been sold.

Article continues after this advertisementAccording to Ana Lopez, Unilever vice president of manufacturing for North America, who was interviewed as part of the study, innovation is key to maintaining customer satisfaction. “Innovation is what will fuel your future,” she states in the report. “At the end of the day, there is no way you could be innovative without being close to your customers and what they want.”

Sustainability policiesBeing customer-focused has also led Supply Chain Leaders to work on their companies sustainability policies and practices, with 86 percent of the group saying it is a “competitive differentiator” (as opposed to just 68 percent of other non-Leaders). The study shows that sustainability initiatives of 69 percent of these Leaders are being guided by their customers’ demands.

Majority are already looking into manufacturing products in a sustainable way (92 percent); sustainability in engineering (89 percent); delivering products with lowest environmental impact (87 percent), and ensuring suppliers are ethically sourcing labor (81 percent).

These Leaders, however, face challenges when it comes to maintaining sustainable after-sales support, as well as ensuring that suppliers are sourcing sustainable materials. Such challenges, states the report, “underscore the need for all organizations—even those with leading supply chains—to increase their visibility into their sustainability practices throughout the supply chain.”

Here’s where data can come in handy, says the report, as a data-driven organization “can react quickly to an unforeseen event or market change and have increased visibility up and down the supply chain.”

The report further reads: “The benefits of real-time insights include increased resilience, greater customer-centricity, increased operational efficiency, superior visibility into the entire supply chain, and seamless collaboration with other functions, partners and suppliers. Supply Chain Leaders are consistently better able to reap these rewards, even though their supply chains tend to be far more complex than others.”

Predictive analytics

According to the study, 51 percent of Supply Chain Leaders use artificial intelligence (AI) and predictive analytics to capture data insights, while only 41 percent of other executives are able to do so.

Such insights can then be integrated with intelligent technology such as AI, machine learning and automation to streamline processes and assist in the effectiveness of IoT (Internet of Things), blockchain, augmented and virtual reality, and drones, the report says.

This requires, of course, an agile and digital tech-savvy workforce, and 92 percent of Supply Chain Leaders say theirs are ready to embrace digital innovation (versus only 60 percent of non-Leaders). According to the report, Leaders are also constantly retraining employees as the technologies continue to evolve.

Finally, the report recommends these other tips for companies aspiring to become Supply Chain Leaders:

• Establish a consistent data flow from design to manufacturing, logistics, planning and maintenance functions.

• Make the supply chain a key part of creating and acting on organizational strategy.

• Focus on achieving visibility across the complete end-to-end supply chain, including suppliers and partners.

• Leverage new technologies (machine learning, AI, IoT) and motivate employees to be part of the journey toward customer satisfaction.

• Continue to break down organizational silos within the company, fostering seamless collaboration between functions.

• Enact sustainability practices throughout design, manufacturing, and delivery for the long term, including supplier practices. —ANNELLE TAYAO-JUEGO