The shredded materials can either be used to make charcoal briquettes or for composting into organic fertilizer. The machine can also convert plastic into other reusable items, such as boards and chairs.

Roland Cordoba, a sanitary engineer, has devised a simple but effective way to reduce waste and facilitate recycling.

His frustration over the slow implementation of Republic Act No. 9003 (Ecological Solid Management Act of 2000), especially the less than successful garbage segregation effort and poor maintenance of materials recovery facilities (MRF), led him to act on his own.

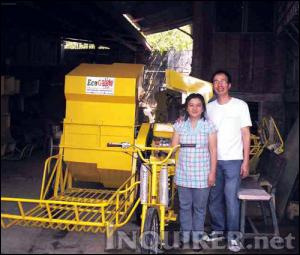

After four years of experiments, his efforts bore fruit. He completed what he now calls the “Eco-Glow machine.”

Cordoba’s idea came upon him as he watched scavengers dig into the garbage dumped at the public market.

Every day, scavengers would look for items they could sell at junk shops, like plastics, bottles and metals.

Vegetable discards, coconut husks and shells, and plastic bags usually make up 80 percent of the garbage heap at the public market, he says.

A garbage truck would haul the pile away unsegregated, Cordoba says.

And since open dumps had been banned under RA No. 9003, the city’s garbage, as well as that of surrounding towns, had to be hauled all the way to the Kalangitan commercial landfill in Capas town for disposal.

Tarlac City and the towns pay huge fees to dump their garbage in Kalangitan, Cordoba says.

With these in mind, Cordoba thought that the hauling of mixed garbage by trucks could be minimized and become less expensive if the residual 80 percent of the garbage could be segregated at the source before transport.

He says scavengers will also earn more if they are given carriers that can do a little more than pushcarts.

From 2002 to 2006, Cordoba designed a machine, conducted experiments and, through trial and error, came up with “Eco-glow” that suited his needs.

He says “eco” stands for ecology while “glow” has been culled from his wife’s name, Gloria, who has been his lucky charm.

Because the materials used are light, the machine can be mounted on a pedicab, according to Cordoba.

The machine is powered by a 13-horsepower, gasoline-fed engine. It can shred at least three tons of mixed biodegradable materials in five to six hours, or two tons of coconuts in the same time. In a separate receptacle, it can pulverize plastic.

If the machine were to be used at dumps, only an estimated 10 percent of residual garbage would be left for garbage collectors, Cordoba says.

He says scavengers can be trained, and later employed, to use the machines.

“This will not only give them added income but, more importantly, decent jobs,” he says.

Cordoba has also designed machines that make charcoal briquettes out of shredded coconut shells and husks, as well as plastic boards from pulverized plastics. These boards can be made into chairs, tables and dividers.

Cordoba says he can fabricate a unit of Eco-glow a week. Each machine is guaranteed to work for five years and may be used by local governments and businesses.

In 2009, Cordoba submitted his project to the Business in Development (BID) Challenge, an annual business plan competition mounted by the Philippine Business for Social Progress (PBSP). It gained the distinction of being one of three most outstanding business plans.

It also won a place in the “triple bottom line category” because the project was community-oriented, eco-friendly and economically viable.