Five years after ‘Yolanda,’ Leyte rice center rises

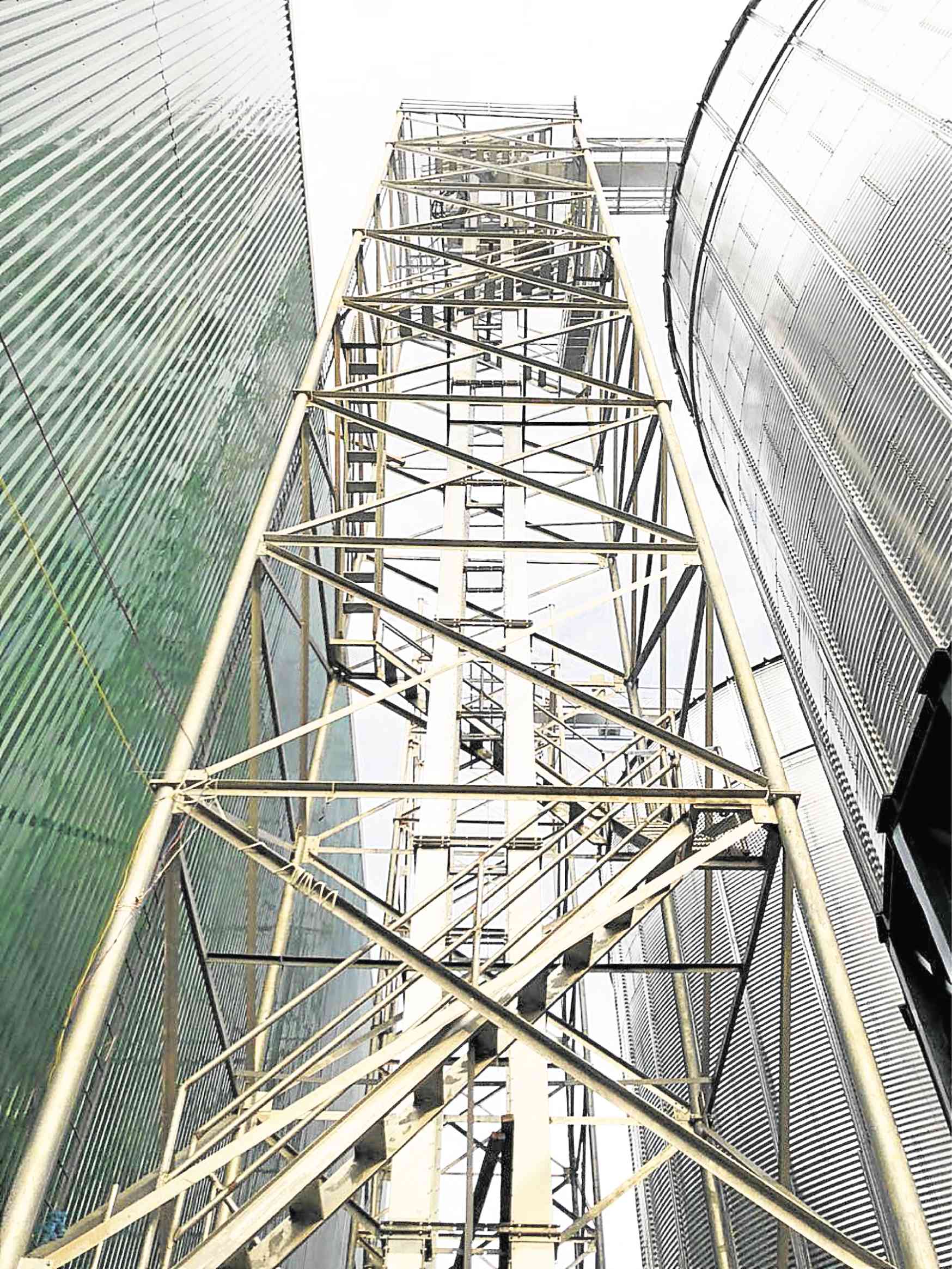

Aerial view of the state-of-the-art Renucci Rice Processing Center (left) put up by Patrick Renucci and Rachel Renucci-Tan

In October this year, after four years of living out of their suitcases in Alangalang, Leyte, and almost five years since supertyphoon “Yolanda” left a trail of destruction across central Philippines, the husband-and-wife team of Patrick Renucci and Rachel Renucci-Tan are finally seeing their dream of a “rice revolution” turn slowly but surely into a multimillion-peso reality.

Last month, the Renuccis successfully tested and commissioned the silos, wet bins and driers that form part of the state-of-the-art Renucci Rice Processing Center, considered the most technologically advanced center of its kind in the Philippines.

Unwavering belief

The Renuccis invested everything they had into the venture, pushed on by their unwavering belief that the Philippines can become more than self-sufficient when it comes to rice, the most widely consumed staple in the Philippines, if farmers are given adequate access to high quality inputs such as seeds, fertilizers and basic mechanization.

Renucci-Tan told the Inquirer in an interview in their home base in Alangalang, a second class municipality about 30 kilometers south of Tacloban City, that the perennial problem of low productivity hounding the country’s rice farmers had little to do with having small parcels of noncontiguous land or inadequate irrigation.

The root of the problem, she said, was the farmers’ lack of easy access to capital to produce adequate farming inputs, including high quality seeds and fertilizers, as well as basic mechanization for them to make the most of their land.

“Their debt trap is also a major culprit as they sell whatever farming inputs they can amass just to be able to pay back their debt to usurious traders who also provide the farming inputs,” she said.

Increased output

What the Renuccis have proven over the past four years of working closely with the farmers that given the right inputs that the farmers can pay through low-interest loans, plus access to basic mechanization to speed up planting and harvesting, farmers can produce at least seven metric tons of rice per hectare, which is comparable to the output in Thailand and Vietnam, two of the world’s leading rice exporters.

This is a giant leap from the current average palay output nationwide pegged by the Department of Agriculture at just four metric tons a hectare.

Such low productivity has made importation of buffer stocks a needed government policy to help stabilize local rice prices.

In 2017, the country’s ricelands only produced a combined 93.44 percent of the country’s requirement, a decline from 95.01 percent in 2016.

Given the typhoons that hit rice-producing areas this year plus the decision to open the country to more imports to tame soaring rice prices, the rice self-sufficiency level may decline even further.

The fully automated, digitally controlled driers bring down the moisture content of palay to the desired 14 percent.

Renucci-Tan contends, however, that the country does not need to import rice at all, if only even just a third of the roughly six million rice farmers across the country get access to adequate farming inputs and mechanization.

She said they had proof of concept with the increase in palay output of the partner-farmers in Leyte.

Full operation

The full operation of the Renucci Rice Processing Center aims to further increase productivity since the palay will be processed properly and efficiently to maximize rice output.

“For the first time, wet palay is precleaned before drying—removing dirt, stones, grass, pests and other impurities. Clean palay is then electronically weighed as part of the drying system to ensure scientifically precise moisture extraction. Simply drying the palay under the sun keeps moisture and pests trapped in the grains. Dried palay is then stored in chilled, fully aerated and temperature controlled wet bins and silos,” she said.

The entire process from palay intake to drying to storage in silos is managed from a single control room, she said. There are virtually no production errors. Production is optimized and costs are reduced, thus boosting the income of farmers.

The Renucci Rice Processing Center was put up by the Filipino-owned Chen Yi Agventures, one of the largest private investments in one of the country’s poorest provinces and in the agriculture sector.

No more doubts

Seeing the giant facility in operation fills the couple with immense pride, and also a sense of relief that they are not as “crazy” as their friends and family said they were when they first broached the idea of leaving their comfortable life behind in Paris to invest in far off Alangalang.

They had reason then to question their sanity as Renucci used to run one of France’s largest printing companies while Renucci-Tan was managing a portfolio of about $1 billion.

But one only needs to walk around the expansive facility and see the happy farmers bringing in their freshly harvested palay for any lingering doubts to quickly and permanently evaporate.