From a backyard venture to a global enterprise

In its 25 years of existence, Mekeni Food Corp. has endured and survived situations that would have forced other similar companies to close shop.

Mt. Pinatubo exploded in 1991 and engulfed in lahar the town of Porac in Pampanga, where the company’s operation was located.

Then the 1997 Asian financial crisis and the 2001 political crisis happened, which caused the peso to plunge versus the dollar, affecting the company’s financial standing. Add to that the news of the foot-and-mouth disease (FMD) affecting the pork industry, the industry Mekeni thrives in.

For Mekeni, a backyard operation that started in 1986, by a husband and wife team who were public school teachers to augment their meager salaries, being resilient and surviving the hurdles meant getting better and bigger.

An opportunity

A bad situation is really an opportunity for a good thing to happen, according to company president Prudencio Garcia, who along with his four brothers, run the Filipino meat processing company that has been recognized for three consecutive years (2004 to 2006) as the best meat processing plant (triple A category) by the National Meat Inspection Service of the Department of Interior and Local Government.

In 2007, it received the grand slam award for the same category.

Mekeni’s state-of-the art plant in Porachas also received an ISO 22000 certification, a global standard which applies to food safety management system. The plant, according to Garcia, is the first meat plant in Asia and in the Philippines and second in the world to receive such certification.

Expansion

The plant, which sits on a 16-hectare lot, has the capacity to produce 100 tons of meat products a day, producing hotdogs, sausages, hams, bacon; apart from tocino, longganisa, and tapa.

Soon the company will be exporting products abroad.

From a backyard industry, Mekeni is now a half-billion-peso company reaching annual sales of P1 billion. It employs more than 1,000 employees and maintains headquarters in Porac and an office in Manila.

GARCIA siblings (from left) Adrian, Nards, Pruds, Tatay Felix (Mekeni Food Corp. founder), Lito and Doods.

The efforts to improve the company to world-class standard were initiated by Garcia and his brothers to counter the challenges and prepare the business for competitiveness in a globalized market.

“The Asian financial crisis and the FMD were a major blow to our operations,” says Garcia. “I told my brothers that in order for us to fight the crisis, we have to change our strategy. Because we are neither big enough nor small enough, we cannot compete against the giant companies or the small companies. We either downsize the operations or upsize. We chose to compete with the giant.”

Garcia started to drastically implement changes such as integrating quality controls and efficient processes. He gathered 40 employees and rallied them to “to think globally and not locally.”

Going global

“To be global, we have to improve our system. The ‘backyard’ industry thinking should be changed. There should be automation, standards, and structures. We have to strictly follow processes.”

Garcia also expanded the company’s meat products beyond the tocino and longganisa, which Mekeni was known for, to hotdogs.

“To be a world-class meat processing company, we need to think of something to compete with the giant. And it’s hotdog. When we entered the market for hotdogs, there were only two known brands. So immediately, we became the third hotdog brand.”

Tatang

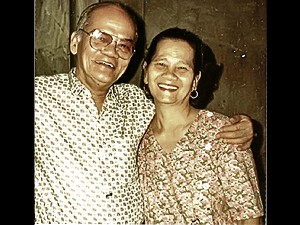

For Mekeni’s transformation to a global company, Garcia credits his father Felix Garcia, who with his wife Meding, started a piggery and meat processing business as a sideline to their jobs as teachers.

“Tatang” according to Garcia acted as the company “visionary” whose words were regarded by the brothers as wise counsel.

“My father is an educator and respected in the community. His words have meaning and he’s always sure of what he says.”

Garcia says his father, the former teacher, through a moving letter, was the one who convinced him and his brothers to give up their successful careers abroad, take over the small-scale family business right after the Mt. Pinatubo explosion.

Garcia was already working as a manager in a cement company in Saudi Arabia, while his wife worked as a nurse there.

“I was at the peak of my life as a professional. I enjoy the community in Saudi. I also had the fear it will be hard to establish connections once I get back. I was out of the country for eight years. But Tatang wrote a very strong letter, reminding us that the reason why we were successful was because of the community. He told us to get out of our comfort zone, expand the business, and rebuild the factory to help people in Porac affected by lahar.”

During the height of the Asian financial crisis and FMD, which nearly forced the company to shut down, Garcia’s father also talked to the brothers to not give up, but consider the people whose very lives depend on the company.

“Tatang told us ‘I promise you someday you will be very proud that you’re working at Mekeni’. It was a simple statement, but the impact was big. Tatang was telling us to not only survive but to grow as an organization.”

Apart from his job at Mekeni, Garcia is also helping other entrepreneurs, particularly micro entrepreneurs, through inspiring talks. As most small businesses are family-run, Garcia tells them to focus on establishing good family relationships first.

“Without good family ties, it will be difficult to run a micro business,” says Garcia, referring to his father’s family that really worked as a team to achieve its goals.

For making a backyard industry into a global business, Garcia is currently a finalist in the SGV Foundation’s “Ernst & Young Entrepreneur Of The Year Philippines 2011.”