Fast forward with CEMEX: building the future now

CEMEX Research Group Head Dr.Davide Zampini and CEMEX Holdings Philippines Philippines Pedro Palomino unveil the “Bayanihan” Concrete which symbolizes nation-building.

“Are you ready for the future? Asked Pedro Palomino, president of CEMEX Holdings Philippines, during the recently concluded 2016 Experts Forum held at the Shangri La Mactan Resort, Cebu. The forum gathered global experts in construction innovation to discuss the newest technologies that are revolutionizing the way we build today.

In the Philippines, construction industry plays a key role in supporting the country’s nation-building capacities. As “the rising tiger” of Asia, the country faces the challenge of sustaining its progressive economy. Having a community of experts at the helm helps ensure the success of this nationwide venture for economic and infrastructure development.

As such the forum themed “Fast Forward : Build the Future Now,” organized by CEMEX Holdings Philippines, gathered over 200 customers and partners in an effort to increase the number of experts who will promote sustainable development for the future.

Thought leaders for CEMEX shared the company’s pioneering product innovations and how these technologies are benefitting the market. The panel speakers was led by Dr.Davide Zapini, CEMEX Research Group (CRG) head. Joining him were Alexandre Guerini product development and industrialization manager of CRG; Steve Crompton national technical director of CEMEX United Kingdom; Engr.Jorge Camilo Diaz Garcia, product development manager CRG for Latin America, and Arch. Enrique Terrado, green building specialist at CEMEX Global Corporate Sustainability.

Experts’ Forum

(L-R) Dr.Zampini; Alexandre Guerini, product development and industrialization manager of CEMEX Research Group (CRG); Steve Crompton, national technical director of CEMEX UK; Engr.Jorge Camilo Diaz Garcia, product development manager of CRG Latin America; and Arch. Enrique Terrado, green building specialists at CEMEX Global Corporate Sustainability.

“We realize that creating great products, great innovations, is not enough. We need to have an emotional intimacy with our customers so we may understand their challenges for us to be able to design our research,” said Zampini.

More than offering unique building solutions, the global brands of CEMEX are also designed to help customers act in sustainable ways.

“Technological innovation is a CEMEX trait,” explained Palomino. “The country is changing and the industry is changing. Eighty percent of our country’s construction products and methods are still in traditional form. We need innovative solutions to fulfil the needs of an evolving market in safer and more sustainable ways.”

Whereas quality products and services as well as reasonable prices are important, the company recognizes the increasing significances of sustainability as a value – added proposition that many customers are now also looking for.

In fact, sustainability is a driving force behind CEMEX’s innovations whose goal is to aptly support the structural challenges of a growing economy. “The heart of our groundbreaking research is to revolutionize the way we build” explained Palomino. “Together let us build the future now.”

Among those in attendance at the forum are representatives from the private and public sectors with proven track record in innovative construction. To name a few, there are AXEIA Development Corporation; DMCI Homes; Cavite Ideal International Construction and Development Corp.; EEi Corporation; First Solid Builders Inc.; First Balfour; Datem Incorporated; Monolith Construction and Development Corp.; DEECON; Concrete Masters, Inc.; Subdivision and Housing Developers Association (SHDA); and the Department of Public Works and Highways (DPWH).

World Class Building Solutions

An artist demonstrates the rapid hardening quality of Promptis by creating an abstract concrete sculpture.

Guerini discussed the company’s building solutions that observe world class standards in terms of quality and capability to deliver on its committed output.

One of these products is Promptis which enables faster construction of pavements and roads that can be opened to traffic within 24 hours – making it ideal for heavily-used roads. The product has been certified by DPWH through Department Order (D.O) 61 Series of 2016 for use of national road projects.

Insularis, on the other hand, works for thermal insulation, which allow customers to achieve important energy savings, improved quality of life, and more comfortable structure for any climatic condition.

Meanwhile, Hidratium has self-curing properties that help customers attain the maximum performance of concrete while doing away with extra investment of time and money for maintenance. Other advantage provided by Hidratium include elimination of plastic shrinkage cracking, reduction of construction time with no post – casting repairs required, production of dust free surfaces, and increase of durability of concrete structures.

Another product innovation is Resilia which can replace steel reinforcements in concrete but nonetheless makes for a product output that, according to the requirement, may even come in the form of thin panel that has hyper strength and hyper ductility. Aside from homes and buildings, it can be used in creating furniture as well due to its flexibility.

Specialized technology

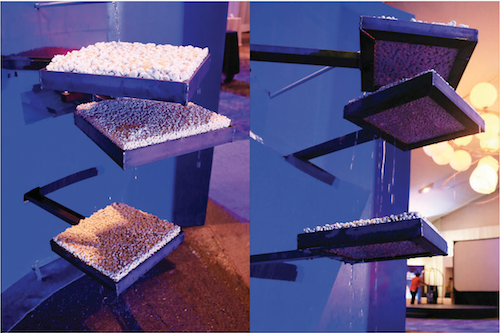

A structural pervious concrete that, like conventional pervious, manages water permeation for draining solutions.

Roads are major construction features in any city. For instance, in the United Kingdom, 95 percent of the roads are paved with asphalt. “The problem is that asphalt roads require maintenance after five to ten years, and costs about three and half billion pounds to maintain in the UK,” said Crompton as he explained about the innovative paving technology that CEMEX is now implementing in the UK and some parts of North America.

The Roller Compacted Concrete (RCC) Paving Solution, he said, proves to be cost effective, resilient, and has lower CO2 footprint compared to asphalt. “The Roller Compacted Concrete Paving Solution allows for initial costs and requires less maintenance. It can also lower fuel consumption of vehicles,” he explained. Another solution for turning rural roads into concrete pavements is the Soil Solidification technology of CEMEX.

First introduced in the UK, RCC which is also available in the Philippines combines the strength and durability of concrete with the ease of construction of applying asphalt. Construction time is also reduced from 60 weeks to six weeks which means tremendous cost savings for clients, according to Crompton.

Meanwhile, place prone to heavy rainfall and flooding can benefit from Pervia (known in the Philippines as Aquacrete) which is a permeable concrete used in paving and housing development. Pervia manages water permeation for draining solutions but nonetheless is still able to carry heavier loads and higher velocity traffic. The concrete has good abrasion resistance and can be contoured, which makes it ideal for making decorative structures and sidewalk decorations as well.

“Pervia is widely used in Europe. Depending on the application, it can give you a level strength and pervious capacities. Moreover, we look at the environmental situation of project and we even recommend an appropriate design for drainage system, along with infrastructure.”

Crompton gave an example of a highway project in Northern England. As a place of experiences heavy rain, apt drainage capacity was installed measuring 400mm wide and 600mm deep.

These ready mix concrete products all contain the company’s very own Admixtures. CEMEX Admixtures offer innovative formulations for special applications, thus is able to deliver the best technical and economical solution.

Urban and rural development

In its goal to be a global leader in sustainable building solutions, strengthening partnerships is another way the company gives back to the people and the environment.

Providing housing for the urban and rural sector is particularly a major challenge because of the growing global population. Diaz tackled Colombia’s housing situation as a case study that showed the continuing need for housing and building solutions.

“In Colombia, around 60 percent of the population wants to live in their own homes. The huge demand for homes account to around 145,000 every year, but only around 100,000 new houses are usually delivered,” he said.

As such, CEMEX actively partners with the local governments and delivers developers’ construction and technology needs for new homes. Some of the company’s key drivers for housing in Colombia are Promptis and Hidratium.

Building resilient cities

Aside from construction, Terrado emphasized the equal importance of building resilient infrastructures especially in cities.

He asserted that sustainability is transparency. “Transparency should be part of concrete solutions for a sustainable future.”

Hence, lowering the company’s carbon footprint and helping customers do the same is a priority for the company. “We have to address climate change together. For this common goal, we partner with the engineers, architects, and other key players in sustainable value chain to create a one-stop-shop that can certify that the infrastructure project adheres to sustainable operations.”

This forms the backbone of CEMEX’s ecoperating seal which calls for infrastructures undergo a rigorous internal process that measures its environmental and social impact. One of the ways to do this through building solutions that abides by this scheme- from using concrete products that have low CO2 footprint, to services such as paperless invoicing, to construction solutions like concrete pavements wih smart LED lighting.

“The buildings in the Philippines go by what is required by national standards but can’t reach international certification. Urban development is also one of the concrete solutions, with road rehabilitation programs, social housing program, and solid urban waste valorization. CEMEX is looking forward to partnering with more resilient cities and explore new ways of effective collaboration. ”

Future-ready

Indeed, a future-ready world requires innovative efforts and collaboration to be made and strengthened at present, Zampini, in his presentation, “Trends of Progress,” further emphasized this in the context of population growth and rapid urbanization.

Theoretically, one new city must be formed for one million people every five days between the preset and 2050, as there will be 9 billion people in 2050, Zampini noted, citing the United Nations. Due to the limited space, living spaces should grow vertically, which are even taller than the mega-tall buildings of today which measure up to 600 meters or higher.

“There will be certain requirements that will be needed unique construction solutions. Moreover, two points are important: health and safety are top priorities in CEMEX, as well as social responsibility. Becoming a good corporate neighbour and supporting nation-building is ingrained in how we do business,” shared Zampini.

As with Mexico and the rest of the countries where CEMEX is present, CEMEX expressed its commitment to help the Philippines become ready for the future by offering a “Bayanihan Concrete” sculpture which was unveiled by Zampini and Palomino during the opening of the grand exhibition of CEMEX’S innovations dubbled “Discovery.”

“This is our gift to your nation which captures what you present: perseverance and hard work. This is your essence in concrete form, and represents our collective effort toward nation-building,” enthused Zampini.

At the Discovery interactive exhibition, the participants of the forum experience the innovative products firsthand through creative demonstrations and live sampling. Also displayed are other specialized concrete technologies such as the Blingcrete, which is light-reflecting and can be used in a variety of applications such as at sidewalks, tunnels, and roads; and the Touchcrete which enabled the guests to automatically switch on the light with just the touch of a hand on concrete panel. ADVT.