SAN JOSE, California—Manufacturing companies may not be able to move their actual production lines into the cloud but they sure can manage there their shop floors, supply chain and inventory, financials and a lot of other tasks crucial in running a manufacturing business.

And what better way to enable manufacturers to focus on their core business—making products—than by lightening up their load on noncore but equally important aspects of their operations by bringing them to the cloud.

For a company to survive and stay competitive in an ever-changing market environment, going to the cloud and keeping connected may be the best way to go. The same goes for brick-and-mortar businesses.

Huge multinational manufacturing companies may not have a problem dealing with the complexities of modern times. With the resources they have, they can establish their own on-premise infrastructure and systems. But others, especially those that do not have the resources to build the systems that will help them become more productive and efficient, may not stand a chance.

It is here where NetSuite Inc., a leading cloud-based business solutions provider, comes into the picture. Its cloud manufacturing solutions were launched at the SuiteWorld 2013—a gathering of NetSuite customers, partners and developers—in San Jose, California last May.

NetSuite chief executive officer Zach Nelson says manufacturing is a complex business. But NetSuite, after years of research and development, is able to come up with a wide range of cloud-based capabilities for people and companies that actually build things.

With NetSuite’s next-generation cloud-based solution, which appeared to be totally unviable before due to the complexity of the production process, Nelson says he now expects a sea of change in the manufacturing industry.

The manufacturing solution is a result of the evolution of NetSuite’s offerings, Nelson says.

“For distributors, we have rich inventory capabilities and all things related to managing items. We saw that some of the distributors were also manufacturers in the sense that they assemble things. So we had, about four years ago, introduced a functionality called white manufacturing, which is really assembly,” he explains.

“Prior to the launch, our products were great for outsource manufacturers—those who do not really make things. They send their materials to somebody else who will build the products and get the finished products for distribution.”

That served as a starting point for the cloud manufacturing solution which was built on top of the existing NetSuite platform, Nelson says in an interview with Philippine and Hong Kong journalists in San Jose.

The manufacturing suite includes a number of functionalities that will allow companies to fully run their businesses end-to-end. These include availability to promise or ATP, standard costs, work-in-process tracking and routings.

ATP is a system that provides visibility to inventory and supply chain, allows direct reservation of sales orders against the supply chain and automates the sales order commitment process.

According to NetSuite, the routing and scheduling capability in the suite allows production managers to define scheduling parameters, such as setup time and run rates for each operation. It also allows the creation of assemblies involving multiple steps and roll-up of standard costs. The work-in-process inventory tracking capability with new multistep functionality enables manufacturers to closely manage work-in-progress inventories to minimize inventory holding costs, prevent stock-outs and maximize efficiency.

The cloud solution covers manufacturing-specific requirements such as shop floor and project control, multisite and multidivision operations and warehousing, demand planning, production engineering, lot and serial control, standard costing, bill of materials and assembly building.

The delivery of real-time visibility into costs and customers enable manufacturers to make data-driven business decisions and adapt swiftly to opportunities and threats.

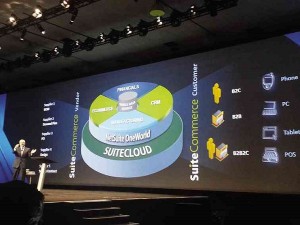

NetSuite SuiteCloud provides a robust environment to customize solutions to meet unique business needs. All customization seamlessly carry over with each periodic upgrade, eliminating users’ concerns that customizations will be lost with an upgrade.

Netsuite’s partnership with 3D design and product lifecycle management (PLM) companies provide its customers with a complete solution to manage product lifecycle—from design to delivery—entirely in the cloud and in one single suite.

An alliance with cloud-based design and engineering software provider Autodesk Inc., which was also announced at the SuiteWorld, will allow NetSuite to integrate its capabilities with Autodesk’s PLM 360, a next-generation cloud-based lifecycle management solution. This, according to NetSuite’s statement, is a major breakthrough in delivering an end-to-end solution for ideation, design, manufacturing, service, multichannel sales and beyond to the manufacturing industry.

“This gives manufacturers a single, closed-loop solution to accelerate product design and development, reduce risk of errors and delays, streamline supply network collaboration and gain critical real-time visibility into pricing, scheduling, capacity and profitability,” according to the statement.

NetSuite has packaged its manufacturing offering with other business solutions, such as financials, enterprise resource planning (ERP) and customer relations management (CRM).

“Modern manufacturers require a system that helps them reduce costs during the design process, efficiently manage multichannel distribution, continuously innovate and leverage a dynamic supply network while adapting to mobile-empowered customers who demand modern e-commerce experience,” the company said in a statement.

It adds that traditional on-premise software used by manufacturers creates a barrier to product innovation and business growth by increasing IT (information technology) costs, therefore driving up the cost of production and decreasing business efficiency and accuracy.

Establishing the traditional on-premise system not only costs a lot but also takes several years to complete. On the other hand, tapping cloud-based solutions is less costly and takes a much shorter time to get the system online.